Foundation Piers

Foundation piering is one of the best methods for repairing settling or sinking foundations. Not only it is up to ten times cheaper than replacing the building foundation, but more importantly it allows to remedy the cause of settlement and level your home back to its normal position so no cracks or other issues related to foundation settlement occur in the future.

There are two types of foundation piers PEP Waterproofing uses to fix settling or sinking foundation – push piers and helical piers. Schematically both types of piers are strong steel tubes driven into the soil with a hydraulic equipment under your home footing. Proper installation of the foundation piers requires driving them down deep enough to hit bedrock or other competent load-bearing strata.

Push Piers

The Grip-Tite foundation push piers are used to fix foundation settlement. The push piers are pushed into the ground with a hydraulic pump until they reach bedrock or other stable strata. After the piers properly installed the load of the structure is fully transferred to the piers through underpinning brackets that are positioned under the footing. The piers are spaced a maximum of 6 feet apart and are used to level or stabilize an existing foundation.

Product Overview

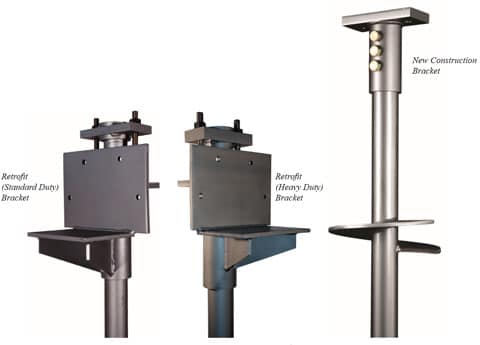

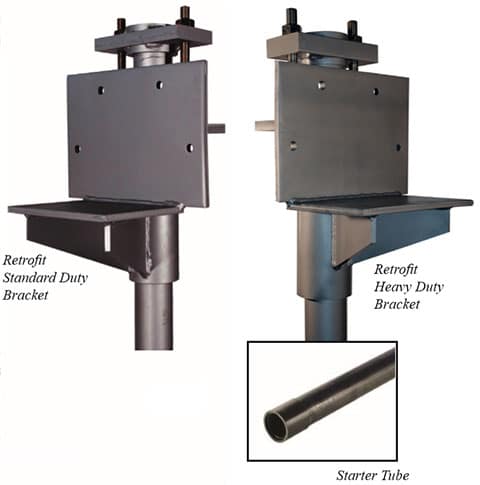

The Grip-Tite push pier consists of pier tube, tube reinfocing insert, and foundation bracket. The push pier parts are manufactured from high strength/low alloy hot rolled steel. Push pier structural tubes are 3″ in diameter. There are two thicknesses for the tubes’ walls; Standard Duty is 0.12″, and Heavy Duty is 0.188″. Also, there are two types of the brackets; Standard Duty Bracket for the most cases, and Heavy Duty Bracket for the special cases.

Foundation pier system is tested by an independent laboratory to peak loads exceeding 70,000 pounds (70 kips).

Key Benefits

- End-bearing pier that does not rely on friction for capacity

- Each pier load tested during installation

- Ability to reach greater depths using a starter tube with friction collar

- High-strength steel pier sections and sleeved couplings have high resistance to bending

- Long life span, resistance to corrosion (design life in moderate soils more than 100 years)

- Available with hot-dipped galvanized coating for added corrosion resistance

Helical Piers

The Grip-Tite foundation helical piers are used to repair an existing foundation structure. The helical piers are screwed into the soil with a hydraulic torque motor until a pre-determined torque is reached. A bracket is then placed on the steel shaft and positioned under the footing of the structure, transferring the load of the structure to the helical piers. The structure can then be stabilized or lifted back level. The helical pier can be both time and cost effective.

Product Overview

The Grip-Tite helical pier are either manufacatured with square or round shafts, and one or more helix bearing plates welded to the shaft. Grip-Tite helical piers have a true helix, meaning the helix and helix spacing along the pile shaft allows the second and/or third helical plate to follow the same general path as the first helix when “screwed” into the soil. This minimizes the disruption of soil.

The helical pier threaded rod ulimate tensile strength is 150,000 psi, yeld tensile strength = 130,000 psi.

Key Benefits

- All-weather installation

- Can be installed with either handheld or small equipment

- Can be installed in areas of limited or tight access

- Foundation concrete can be poured immediately following installation

- Lead sections can be configured to achieve design depth and capacity

- Cost-competitive versus other deep foundation alternatives

- Vibration-free installation (unlike traditional driven piles)

- Installs quickly without generating spoils